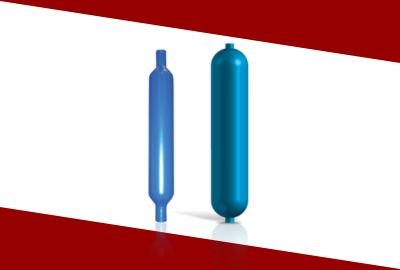

We are leading Pressure Vessels manufacturer in Pune. High integrity, high reliability pressure vessels, towers, and columns are provided by Ultraweld Coat in almost all engineering metals utilized in the process sector. Pressure vessels from Ultraweld Coat are made to function safely at a particular temperature and pressure. As per code stamp, Ultraweld Coat is authorized by ASME ‘U’ & ‘R’ Stamp to be used in the production of pressure vessels. Reputable international inspection organizations like LLOYDS, TUV, BUREAU VERITAS, AKER KVAERNER, UHDE, and TOYO have certified Ultraweld Coat’s pressure vessel manufacturing. As a leading Pressure Vessels Suppliers in Pune,the kinds of vessels that Ultraweld Coat provides are:

As a leading Pressure Vessels Suppliers in Pune we are offering top quality advanced technology vessels which suited to your business needs.